Digital high performance measuring system for hysteresis and demagnetisation measurement of hard magnetic materials like material and flux measurement of flat samples and flux measurement of ferrite segments according to BOSCH standard.

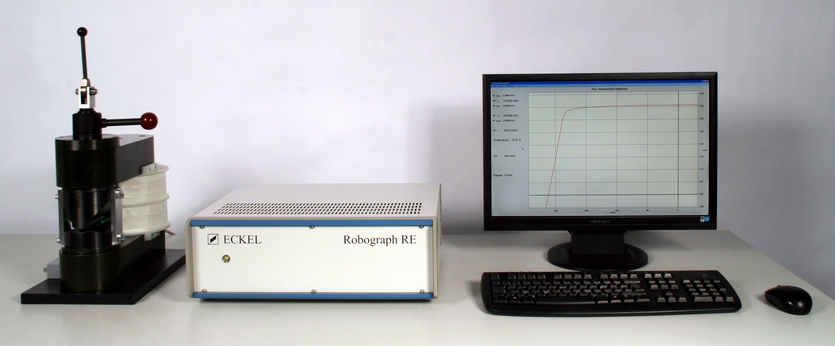

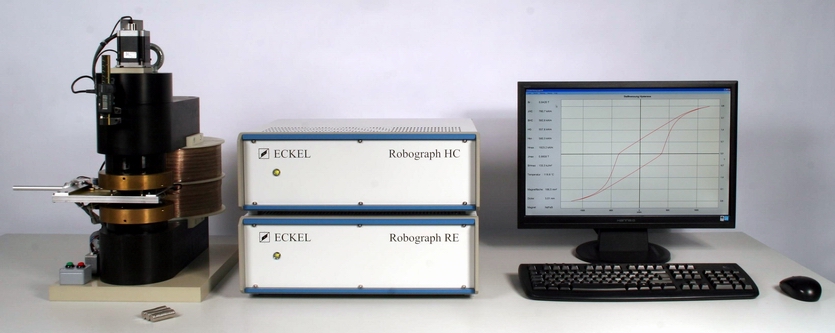

After 15 years of worldwide success since the introduction of Robograph 2 ECKEL presents the new Robograph RE (Rare Earth).

With complete new digital technology the Robograph RE sets new standards in hysteresis and demagnetisation measurement of hard magnetic materials.

While functions of flux hysteresis measurement of ferrite segments according to Bosch specification with some improvements mainly stay the same as with the Robograph 2, new ways are opened for measurement of flat samples of Rare Earth, AlNiCo or ferrite material. Also flux measurement of flat samples with air gap is possible.

A hysteresis measurement instrument determines the properties of a magnet by simultaneous recording of field strength and magnetic flux respectively induction over a preselected field range. Thereto the magnet must be exposed to an external magnetic field.

For hysteresis measurement normally the magnetic field is driven to positive and negative saturation. If field strength is not sufficient for this, only demagnetisation measurement is possible. Here the field is only driven in one direction opposing to the internal field of the magnetized magnet.

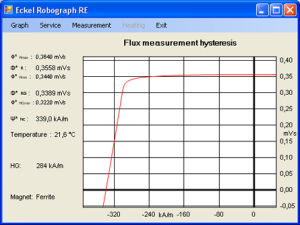

The display of all data results in the desired graph.

All competitors hysteresis measurement instruments offered for this purpose consist of two analogue integrating flux meters with digital display and with the results being read and displayed via PC. Only some values per second can be read by this method.

In contrast to that, all test inputs of the Robograph RE are digitally sampled and processed by a PC.

The software of the Robograph RE allows for a signal processing like offset correction, switching of amplifications and time outs during measurement, which would not be possible with analogue systems.

The extraordinary signal quality of the Robograph RE nevertheless allows an evaluation without any direct signal conditioning or filtering.

Resolution of analog/digital converters is 24 Bit (16.777.216 steps) at sample rates from 125 Hz to 2.000 Hz. Output noise of the power amplifier has been minimized. By different input amplifications (1, 2, 4, 8, 16, 32, 64 and 128) the measuring signal is levelled to optimum. Input noise is only 1 ppm of full-scale at input amplification of 1. Thereby repeatability is improved to better than 0.1% (if magnet stays in fixture). Thus the result is shown with one more digit as usual (0.1 µVs, 0.1 mT and 0.1 kA/m resolution).

Using a PC as an integrator provides higher performance at significantly lower costs if compared to two high-quality analogue flux meters. By evaluating data via software the Robograph RE benefits permanently from performance enhancements which are provided by software updates. Also firmware of the Robograph RE can be updated by the user. Adequate programs will be provided at our website.

The Robograph RE is connected to the PC via USB

To generate the magnetic field the Robograph RE has 2 controlled power current sources. Output of the power amplifier is 1.400 VA and the fan is temperature regulated.

The Robograph RE has complete control over all voltages, currents and temperatures of the power amplifier. Stability of the power amplifier has been tested with 100.000 measurements at non-stop operation.

Since excitation of the power amplifier is digital, the time course of field strength can have any shape.

With different speeds and selectable maximum field strength hysteresis measurement as well as demagnetisation and 2-quadrant demagnetisation or even loops or recoils are possible. Also New Curves of unmagnetized magnets can be shown.

After measurement demagnetisation or hysteresis curve are shown as selected. The graph can be expanded by mouse as desired until single dot display. As usual all results can be temperature compensated.

Display of Hall probe and coil signals is possible. All graphs can be printed.

As power supply for the Hall probe the Robograph RE has a symmetrical current source switchable from 7 mA (flux hysteresis measurement) to 5 mA (Rare Earth material measurement).

The Robograph RE is self calibrating at all input amplifications and has a reference signal output to perform an external calibration and certification using any calibrated multimeter.

Resolution, repeatability, speed and easy handling of the Robograph RE have never been reached before.

The Robograph RE software needs a Windows operating system and is available in English and German.

Flux hysteresis measurement of ferrite segments according to Bosch specification

The Robograph was designed in co-operation with Robert Bosch GmbH and the aim of the design was the automation of the Bosch test specification No. 3 139 918 950 for non-destructive flux measurement of magnetic segments.

The traditional way of testing the quality of magnet segments by material test of single surface ground segments should not be performed anymore. The number of samples taken was too low to obtain a reliable statement for an entire delivery as too many efforts were involved with the grinding process. Apart from that, errors occurred when the radial preference direction was not considered or when the surfaces were not parallel. Furthermore, length and width which affect the magnetic flux, and especially the thickness of the segment, were not considered in the measurement.

With the flux measurement according to Bosch test specification No. 3 139 918 950 the segment is held inside a measuring fixture which resembles the individual pole housing and is magnetized in both directions beyond the saturation point. The magnetic flux is measured by means of a surrounding coil and the magnetic field is measured by means of a Hall probe. Full hysteresis is always measured.

These flux measurement fixtures can be obtained by us for Robograph RE as well as for Robograph 2.

As results of the flux measurement the remanence flux Φ*R and the remanence flux Φ*RG after an opposing field H*G are indicated. Also the value HGF(80) can be evaluated. These values are compared to the limit values which have been calculated for this magnet. By default a demagnetisation curve with display of tolerances is shown.

The Bosch test specification No. 3 139 918 950 demands the measurement of a minimum number of magnets of each batch and a statistical evaluation with determination of the Cpk value. This value provides information about the usability of the entire batch. The Robograph RE unit provides an automatic calculation of the Cpk value.

The flux measurement can be applied for each magnet which allows for a measuring fixture with a diameter of no more than 100 mm. At a magnet thickness of more than 10 mm, a test on whether the magnetic material can still be saturated must be performed.

The Robograph RE provides the calculation of flux measurement fixtures and the approximation of limit values based on the magnetic geometry of magnet segments for fractional-horsepower motors. Bosch is using the more accurate FEMAG field calculation program for the determination of limit values.

In a continuous calibration system the Robograph is also used for manufacturing calibration pole housings for flux measurement of finished pole housings. This flux measurement is preferably performed using the ECKEL DFM flux meter.

Both at Bosch and at its suppliers, the quality inspection of magnet segments is already based worldwide on the use of Robograph hysteresis measurement systems. On page “References” you will find an extract from our customer base, where addresses of market leading companies regarding magnet technology are listed.

Meanwhile the Bosch test specification has become a worldwide standard that is also applied by other companies and thus demanded from their suppliers.

Measurement speed and fixture geometry (air gap) stay the same to get the same results as with the Robograph 2. Therefore all parameters except input amplification are fixed at this measurement. Sample rate was increased from 900 Hz to 2.000 Hz.

The Robograph RE and the new fixtures have been tested and approved at Bosch by comparing to the Robograph 2.

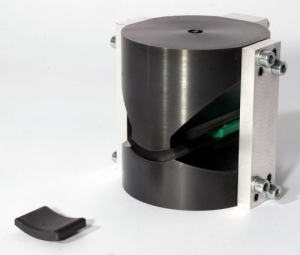

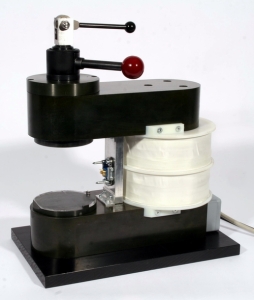

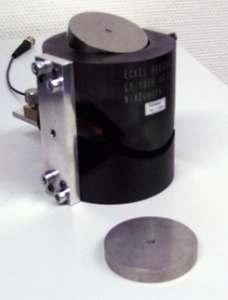

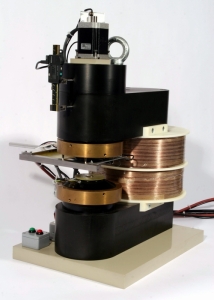

The electromagnet yoke for flux measurement of ferrite segments has been significantly reduced in size and weight compared to the Robograph 2 at same magnetic power (from 180 to 70 kgs). The new horseshoe shape guarantees simultaneous saturation of all yoke parts at minimum magnetic path length. The measurement yoke can only accept flux measurement fixtures.

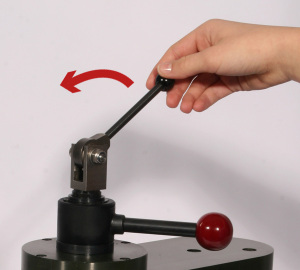

Changing the fixtures is now a matter of seconds. To open the yoke only one movement is necessary.

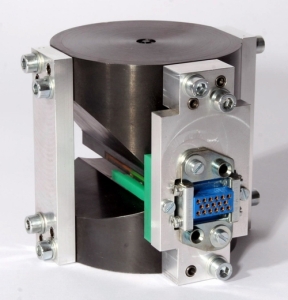

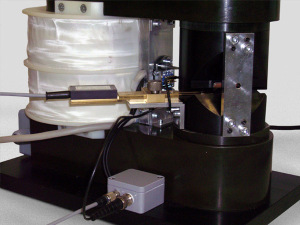

No cables are to be connected and no Hall probe to be entered. The new fixture has an inbuilt hall probe and a special plug, connecting coil, Hall probe and parameter EEPROM to the Robograph RE. The plug has a floating fit and guaranteed 100.000 mechanical cycles. The plug holder gives additional stability to the fixture.

The Hall probe holder offers additional position control for the magnet and is made from plastics to prevent errors by eddy currents around the Hall probe. No cable can be damaged when pulling out the fixture.

When entering the fixture, the Robograph RE recognizes the fixture and reads magnet number, number of turns (standard = 50), Hall probe parameters, temperature coefficients and flux limits from the EEPROM. These values are used for measurement evaluation. By different input amplifications the fixtures now can be produced with lower number of turns.

The magnet segment has no longer to be fixed by plastic stripes but is perfectly fixed with a bolt, pushed down by one sweep of the hand. The bolt has a below end of brass to ensure the air gap.

All this simplifies and speeds up handling significantly.

The new yoke can also be used with the old fixtures of Robograph 2. It is not necessary to change all fixtures. By inserting 2 metal discs of 60 x 10 mm the old fixture can be used. If it is only used with the new Robograph RE, these discs can be fixed with glue.

Of course connecting cables, entering the Hall probe and fixing the magnet by plastic stripes is still necessary with old fixtures.

The Robograph RE in this combination with the small yoke replaces the Robograph 2 and is available from now on.

Measurement of flat magnets (ferrite, AlNiCo and Rare Earth)

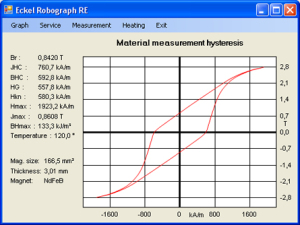

With the big yoke also Rare Earth magnets and other flat samples can be measured. Standard measurement is material measurement (Br, HG, BHC, JHC, B*Hmax) as hysteresis or demagnetisation. But also flux measurement (result in mVs) is possible with or without air gap. This yoke has also been optimized in size, weight and performance.

The yoke holds a pair of flat heatable pole shoes made from cobalt steel with a saturation of 2.35 T. The usable diameter is 63 mm by default. Other sizes are possible on request. The pole shoes are used in combination with a J-compensated surrounding coil. For evaluation surface area of the sample must be known and must be constant over thickness. Thickness is recorded automatically.

Depending on sample thickness maximum field is up to 2.100 kA/m. A JHC can be evaluated up to 1.800 kA/m.

The surrounding coil consists of a 7-layer PCB with 2 printed coils and an integrated Hall probe. It is available in different diameters and shapes and is exchangeable. Parameters of the coil are read by the Robograph RE automatically. The coil is calibrated by a PTB certified comparison coil. For compensation of field widening at larger air gap a thickness dependent calibration is performed.

For measurement the magnet is clamped backlash-free between the pole shoes within the coil opening.

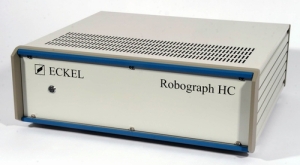

The pole shoes can be heated up to 180 °C by using the Robograph HC (Heat Control). The Robograph HC has two independent regulated DC current sources of up to 700 VA. After some minutes the Robograph HC reaches the selected temperature and keeps it constant also during measurement for +/- 0.1 °C. The temperature is acquired by Platinum surface sensors.

As the Robograph RE the Robograph HC is completely controlled and regulated internally. It is also connected to PC via USB and firmware can be updated.

The measurement is completely automatic even with heating up. Coil and yoke are motorized and equipped with sensors. The yoke is controlled by the Robgraph RE via serial interface (RS232).

The magnet is inserted magnetized or unmagnetized by hand. For this a positioning template is available. Measurement can be started by button at the yoke or by keyboard / mouse.

The yoke is driven down near the magnet until light barrier alarm, the coil is pulled in and the yoke is completely closed until contact detection. Then the selected measurement starts. At the end the yoke is opened and the coil pushed out. For more easy removal of the magnet it can be ejected on pressing a button.

If heated measurement is desired, the yoke first is completely closed, the magnet heated, then the yoke is opened again a little bit and measurement gets started. To keep the magnet from sticking on the upper pole shoe, the coil has a stainless steel sheet for heating.

The complete automatic procedure is not only very comfortable but also ensures exact repeatable results, fast execution and temperature stability at the beginning of measurement after heating up.

Procedure of flux measurement is mainly the same. Since flux measurement shall simulate the situation within the motor, an air gap is needed. For that there are coils that create a magnetic air gap with PCB material (e.g. 0.5 mm). The magnetic shear of hysteresis at this measurement is part of the result and is evaluated analogue to flux hysteresis measurement of ferrite segments. But flux measurement can also be performed as demagnetisation measurement and of course with heating. The user can select between standardized J curve (horizontal in Φ*R) and real J curve (with slight gradient in Φ*R).

For unheated material tests of flat ferrite or AlNiCo magnets also pole shoes with internal coils can be used. The magnet is clamped backlash-free between the coils of one of the coil pairs. The induction B is measured using this coil pair. The second coil pair is used for J-compensation. The field strength is measured using a Hall probe. Here the surface area of the sample may be unknown and may be not constant over thickness. The coil must be covered completely be the magnet.

Sample rate, measurement speed and maximum field strength are selectable. Hysteresis, demagnetisation and 2-quadrant demagnetisation (with magnetisation at the beginning) with or without inner loops can be selected. Also New Curves of unmagnetized magnets can be recorded. Even back-coupled functions with constant dB/dt, dΦ/dt or dH/dt as well as temperature coefficient evaluation are available.

Measurement time and number of samples are depending on the selected parameters. Measurement time is between 8 and 150 seconds. The number of samples is set to about 10.000 samples for a complete hysteresis.

Evaluation and display of the result take less than one second. All results that can be calculated from a hysteresis or demagnetisation curve can be displayed. If desired, a tolerance can be set for all results. Of course all results can be archived, printed and exported.

A Rare Earth magnet normally cannot be magnetized by the Robograph RE at all temperatures. For demagnetisation measurement most times an external magnetizer is necessary for prior magnetisation.

Also a complete physical demagnetisation is not possible with the Robograph RE. Therefore an external demagnetizer is used.

The Robograph RE as complete version together with the big yoke and the Robograph HC will be available from summer 2010.

In this combination the Robograph RE replaces the hard magnetic part of the Universal-Magnet-Measuring-System (UMMS).

Features of the Robograph RE:

Internal, automatic calibration of the device, no offset calibration of analogue integrating flux meters.

The internal ultrahigh accuracy symmetrical reference voltage source (combined with the calibration software integrated in the system) performs a calibration of all test inputs within some seconds. By using an external calibrated multimeter this internal calibration can be checked by means of integrated control software and a calibration certificate can be issued.

Measurement of the complete hysteresis curve within a minimum of 8 seconds with high resolution (approximately 10.000 dots).

Other slower units often only measure the demagnetization curve to save time. With that kind of process an offset error of the analogue integrators can corrupt the result, although the error cannot be identified visually. With the high resolution of the Robograph RE there are no knees of the curve, which may however be usual when using flux meters being read by PC.

Self-explanatory Windows user interface with one-key control after pre-selection of operating mode.

Operating the Robograph RE unit does not involve working with complicated menu sections. All information and the results with regard to the measurement are presented on one single page. The desired process regarding the measurement, the evaluation, the presentation of a graphics, the printout and the archiving are pre-selected and can afterwards be performed automatically, or if desired by operating a push button at the measuring yoke.

Extensive parameter settings.

Using parameter settings allows for a set-up of the measurement according to individual requirements.

Software and operating manual in German and English.

The language of the user interface will be selected by a parameter setting and the operating manual is also available in German and English as pdf file. The operating manual is continuously updated with informations about software upgrades.

Archiving of measurements and tolerance archive for all segment types and materials.

If you want to review measurements at a later point in time, you can save all measurements. This can be performed on the local hard disk, or the Robograph unit can transmit this data to your network server. Also the measurements can be exported as EXCEL file. All original samples are archived each time. For each magnet type at the flux measurement and for each material at the material test the individual limit values are set one time and are then stored. Before the measurement is started, the tolerance data to be applied will be loaded.

Temperature compensation for ferrite and Rare Earth materials.

As the limit values for the magnets are related to a temperature of 20 degrees Celsius, the Robograph RE unit has integrated temperature compensation in order to convert temperature-dependent results to 20 degrees Celsius.

Troubleshooting programs.

If you doubt a measurement result or if one of the various control routines reports an error, you can rely on a number of control programmes integrated in the unit that allow for error analysis with regard to simple operating errors up to defective individual PCB assemblies. A graphical debug surface allows control over all voltages, currents and temperatures of every single transistor.

Technical Specification:

Requirements:

Pentium PC, LCD monitor, Windows XP – Windows 7.

The completely installed PC (Windows 7) is included.

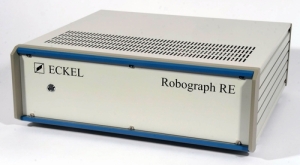

Robograph RE Desktop:

- 2 controlled 700 VA bipolar power current sources suitable for continuous operation with thermal protection and forced ventilation

- Sampling of 4 measuring inputs with up to 2.000 Hz at 24 bit resolution

- Max. measuring error: +/- 0.2 %. Magnets must be inserted carefully!

- Typical device-related measuring error: < 0.1%

- Data transmission to PC via USB interface at 12 Mbit/s

- Microprocessor control for all internal processes

- Self-calibration by means of internal reference

- Power supply: 1.600 W, 230 V or 115 V (please specify when ordering)

- Dimensions: 19″, 3HE (height units), W47 x L44 x H17 cm

- Weight: 20 kg

Robograph HC Desktop:

- 2 controlled 700 VA power current sources suitable for continuous operation with thermal protection and forced ventilation

- Data logging for 2 temperature measuring inputs with up to 1.000 Hz at 16 bit resolution

- Regulation accuracy: +/- 0.1 °C

- Data transmission to PC via USB interface at 12 Mbit/s

- Microprocessor control for all internal processes

- Power supply: 1.600 W, 230 V or 115 V (please specify when ordering)

- With 230 V 16 A fuse or with 115 V connecting the Robograph RE and the Robograph HC to separated circuits is recommended.

- Dimensions: 19″, 3HE (height units), W47 x L44 x H17 cm

- Weight: 18 kg

Small measuring yoke:

- Modulation up to approximately +/- 1.000 kA/m at magnet thickness of 6 mm

- No measurement of Rare Earth magnets!

- Seating for new and old and flux measurement fixtures

- Built-in temperature sensor (PT) for temperature compensation

- Weight: 70 kg

- The measurement fixtures are depending on the dimensions of the magnets.

Large measuring yoke:

- Modulation up to approximately +/- 2.100 kA/m at magnet thickness of 2 mm

- Acceptance of heated and unheated pole shoes.

- Maximum opening about 40 mm

- Temperature proof for pole shoe temperatures up to 180 °C

- Temperature sensors (PT) for temperature measurement and/or compensation on the pole shoes

- Motor control and sensor evaluation by microcontroller

- Data transmission to Robograph RE via RS232 at 115.000 Kbit/s

- Power supply 12 V, 3 A DC

- Weight: 150 kg

A visit at the customer for local training normally is not necessary but can be ordered optionally.

The Robograph 2 unit comes with a two-year guarantee and a 10 year service guarantee as well as an optional software update service including updates of the operating manual.

Deutsch

Deutsch English

English